Mar. 15, 2024

In the realm of engineering technology, both metal hoses and flexible metal conduits serve critical roles in various applications. While they may appear similar at first glance, there are distinct differences between the two that are important to understand. Let's delve into the characteristics and applications of metal hoses and flexible metal conduits to clarify their differences.

Metal Hose: Composition and Characteristics

A metal hose consists of corrugated flexible pipe, a net sleeve, and joints, making it an essential connecting component in engineering systems. Typically made of austenitic stainless steel or according to customer requirements, metal hoses boast excellent flexibility, corrosion resistance, high temperature resistance, and high pressure resistance. They are designed to compensate for temperature variations, absorb vibrations, reduce noise, and facilitate changes in the direction of media transport. Metal hoses play a crucial role in mitigating displacement between pipelines and equipment.

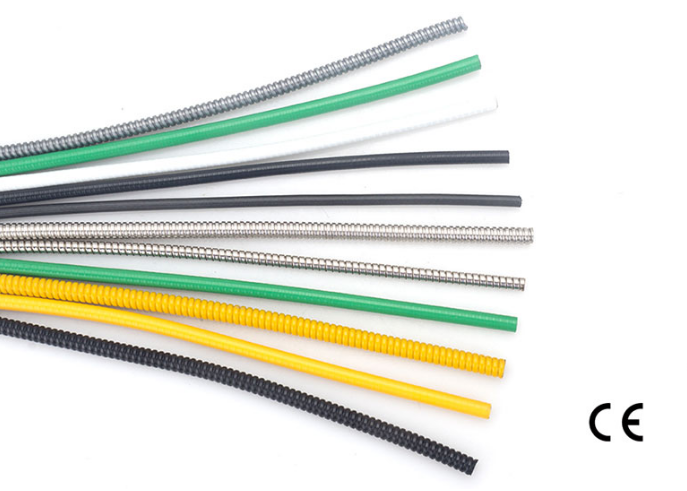

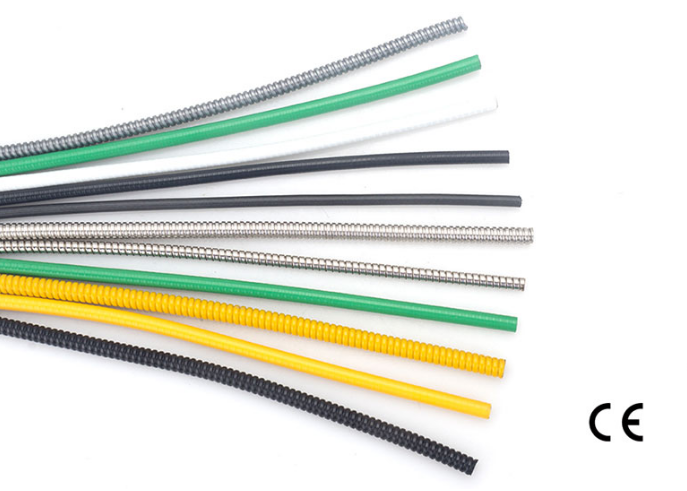

Flexible Metal Conduit: Composition and Characteristics

On the other hand, flexible metal conduit is primarily composed of PA (polyamide) and is suitable for use in temperatures ranging from -40°C to +115°C. These conduits are typically black in color, although other color options may be available upon consultation. Offering high flexibility and resistance to ultraviolet rays, flexible metal conduits come in a variety of specifications to meet diverse needs. They serve as protective enclosures for transmission signal lines, wires, cables, and fiber optic cables, safeguarding them from external damage. Additionally, they are commonly used in infrastructure projects and industrial settings to protect cables and wires from harsh environments.

Key Differences Between Metal Hose and Flexible Metal Conduit

1. Composition: Metal hoses are typically made of austenitic stainless steel or other materials specified by customers, while flexible metal conduits are primarily composed of polyamide.

2. Application: Metal hoses are primarily used as connecting components in engineering systems, offering flexibility and resistance to corrosion, high temperatures, and pressure. Flexible metal conduits, on the other hand, serve as protective enclosures for transmission signal lines, wires, cables, and fiber optic cables, safeguarding them from external damage in various environments.

3. Flexibility and Functionality: While both metal hoses and flexible metal conduits offer flexibility, they serve different functions. Metal hoses compensate for temperature variations, absorb vibrations, reduce noise, and facilitate changes in the direction of media transport. Flexible metal conduits primarily provide protection for cables and wires, ensuring their integrity and longevity.

Choosing the Right Solution

When selecting between metal hoses and flexible metal conduits, it's essential to consider the specific requirements of your application. If you need a connecting component that offers flexibility, resistance to corrosion, and high temperatures and pressures, a metal hose may be the ideal choice. On the other hand, if your priority is to protect transmission signal lines, wires, cables, or fiber optic cables from external damage, flexible metal conduits would be more suitable.

In conclusion, while metal hoses and flexible metal conduits may share some similarities in terms of flexibility, they serve distinct functions in engineering systems. Understanding their differences and applications is crucial for selecting the right solution for your specific needs.

For inquiries about metal hoses, flexible metal conduits, or other high-quality products, please don't hesitate to contact us.