Jan. 17, 2020

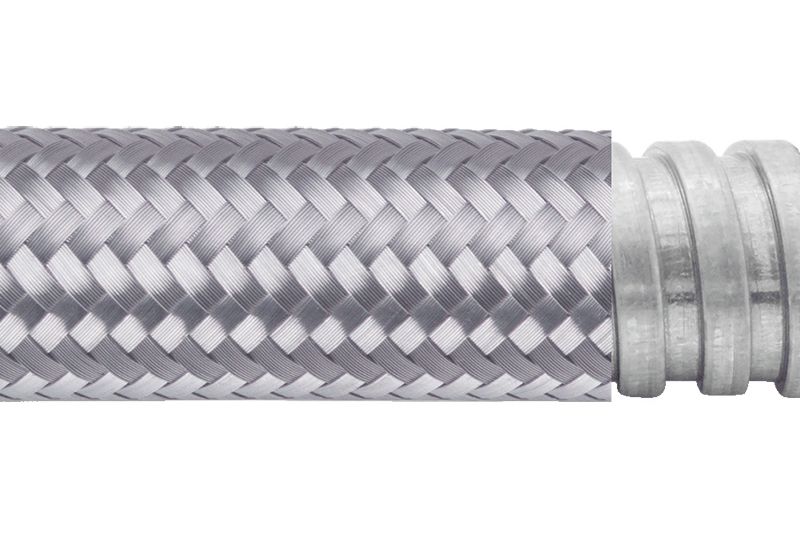

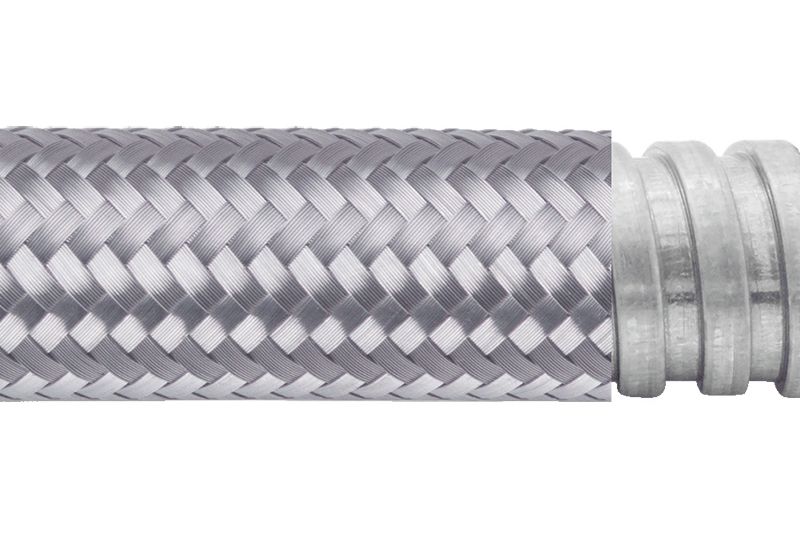

Flexible Metal Conduit is a flexible part with excellent

performance in modern industrial pipelines. The structure is a stainless steel

metal hose braided with one or more layers of steel wire or steel belt net

sleeves, and the ends are equipped with joints or flange heads for conveying

various media. Its characteristics: corrosion resistance, high and low

temperature resistance, light weight, small size, good flexibility.

Flexible Metal Conduit EMI Proof

The main purpose:

1. Conveying corrosive chemical media or organic solvents. (Such as: nitrogen

water, acetone, etc.) 2. Transport high temperature gas, hot oil and other high

temperature media 3. Transport low temperature or ultra low temperature media 4.

Transport water, gasoline and other media under high temperature environment. 5.

Pipes that need vibration damping or noise reduction. Aluminum Flexible

Metal Conduit Supplier introduced the widespread use of metal hoses in

various industries. In actual processing and use, there are often some reasons

for metal hose damage. This is where we need to pay attention, and then we will

take everyone to understand the protection points of metal hoses. The following

are the reasons for this:

1. Metal hoses to be transported to the site should be stacked and neatly

stacked, and they should not be stepped on.

2. The metal hose should be covered and protected to prevent wind and rain

from aging it in advance.

3. The metal hose should be cut straight and not beveled.

4. Method of metal hose connector: A large metal hose with a length of 0.3

meters should be outsourced at the metal hose connector, and both ends must be

tightened in half, with no gap left in the middle. In order to ensure that there

is no gap in the middle, the ends of the two joints should be marked. When done,

wrap it tightly with tape to prevent slurry leakage.

5. The position of metal hoses must be accurately positioned, especially near

the joints. The distance between the reinforcing bars of the metal hoses must be

0.5 meters, which is indispensable.

6. When the welding rebar is close to the metal hose, take measures to

protect the metal hose from being burned. If you accidentally get burned, the

burn should be wrapped tightly with tape.

7. Considering that the number of metal hoses on the top plate is gradually

decreasing, all parts that conflict with metal hoses should avoid metal hoses.

8. When pouring concrete, do not put material into the metal hose. Vibrators

must not collide with metal hoses. It is strictly forbidden for two vibrators to

vibrate with a metal hose in between. Especially when the web is vibrated, it is

strictly forbidden to vibrate the vibrator at the same position for a long time.

The vibrating time shall not exceed 20 seconds.

9. When removing the mold, pay attention to protect the leaking metal hose at

the end.

The above points need everyone's attention. These problems can be avoided by

paying attention and careful attention during construction, and paying attention

to these details. If the above problems occur, resulting in damage to the metal

hose, it should be replaced immediately without construction to avoid loss. Our

company also has Flexible Metal Conduit EMI Proof on sale,

welcome to consult.