Jan. 06, 2022

Electrical Flexible Conduit often encounters a variety of

problems during the construction process. The most common problem is the

excessive resistance encountered during threading. In fact, there are many ways

to solve this situation. In the early stage of construction, We can prevent this

from happening as long as we do a good job. Let me introduce the specific

reasons and solutions.

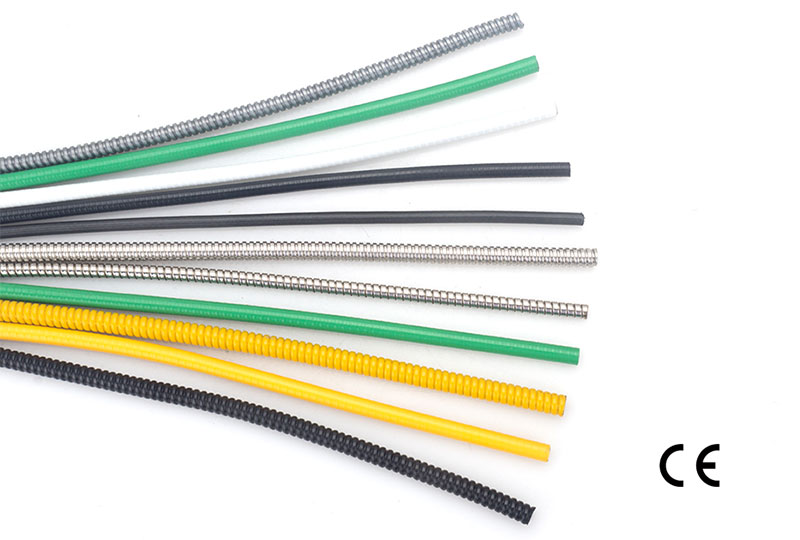

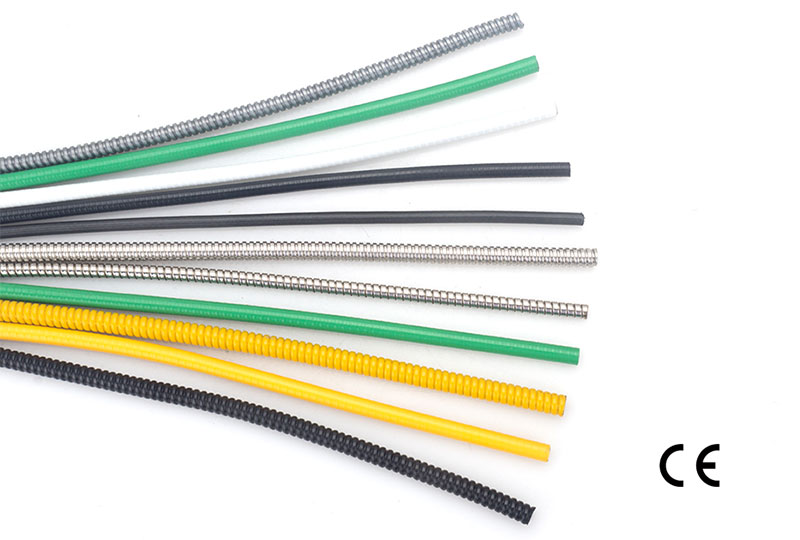

Electrical Flexible Conduit

The joints of flexible electrical conduits need to be tightened before

construction and the tightening method is also required. First, unscrew the

fastening nut of the connection joint and place it on the inner wall of the box

(box), and then tighten the connection joint with a wrench Just the nut.

Protective measures such as adding protective tubes should be taken when the

foundation of the building or when it may be exposed to significant mechanical

impulse. Compensation devices should be installed when passing through

settlement joints or expansion joints. Flexible electrical conduits should be

neatly arranged and firmly fixed when exposed, and the spacing between their

fixing points should be uniform. The distance between the tube clamp and the

terminal, the midpoint of the turn, the edge of the electrical appliance or

equipment is 150mm ~ 300mm, and the fixed tube clamp in the middle of the

pipeline The large distance is 0.5 ~ 1m, and the distance between fixed points

should be uniform, and the allowable deviation should not be greater than 30mm.

The allowable deviation of the horizontality or verticality of the exposed

flexible metal wire protection sleeve laid horizontally or vertically is 5%, and

the deviation of the total length should not be more than 1/2 of the inner

diameter of the pipe. When the flexible metal wire protective sleeve is

concealed, it should be laid along the near route, and the bending should be

reduced. The small distance between the metal sleeve buried in the building and

the building surface should not be less than 15mm; laying in the cast-in-situ

concrete It should be fixed with steel bars when the distance is not more than

500mm. When the flexible metal wire protection sleeve is routed after piping,

the total cross-sectional area of the conductor in the pipe including the

insulating layer should not be greater than 40% of the empty cross-sectional

area of the pipe. When the flexible metal wire is used to protect the sleeve

or the bend is long, to prevent damage to the wire due to excessive resistance

when the Priica pipe is threaded, the distance between the two junction boxes or

the cable box is specified: no more than 30m when there is no bend; When there

is one bend, it does not exceed 20m; when there are two bends, it does not

exceed 15m; when there are three bends, it does not exceed 8m.

Windable metal tube can absorb vibration, it can not only improve the

system's ability to fatigue damage, but also can achieve the effect of reducing

noise. This is why some piping systems use Flexible Metal

Conduit.

After the metal reacts with oxygen in the atmosphere, an oxide film is formed

on the surface. The iron oxide formed on ordinary carbon steel continues to

oxidize, causing the corrosion to continue to expand

Large, eventually forming holes. Carbon steel surfaces can be electroplated

with paint or oxidation-resistant metals (for example, zinc, nickel, and

chromium).

As is known, this protection is only a film. If the protective layer is

broken, the underlying steel begins to rust.

We are Electrical Flexible Conduit Factory, welcome to

consult.