Aug. 26, 2020

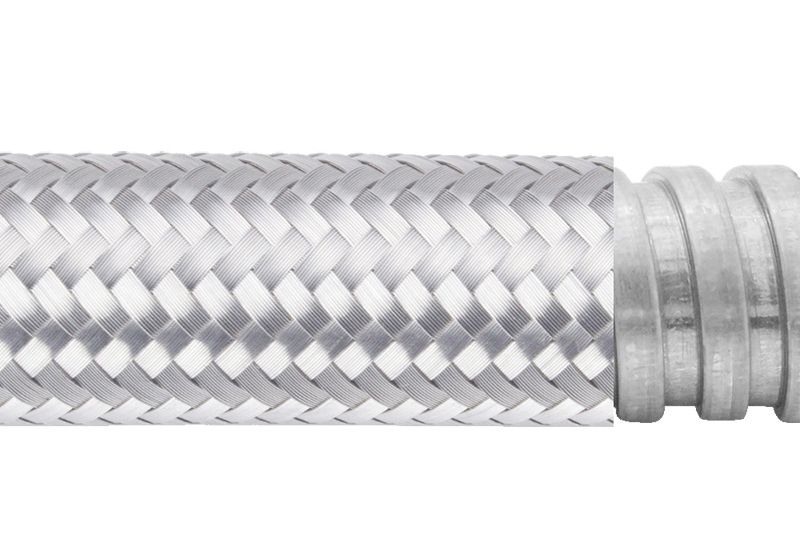

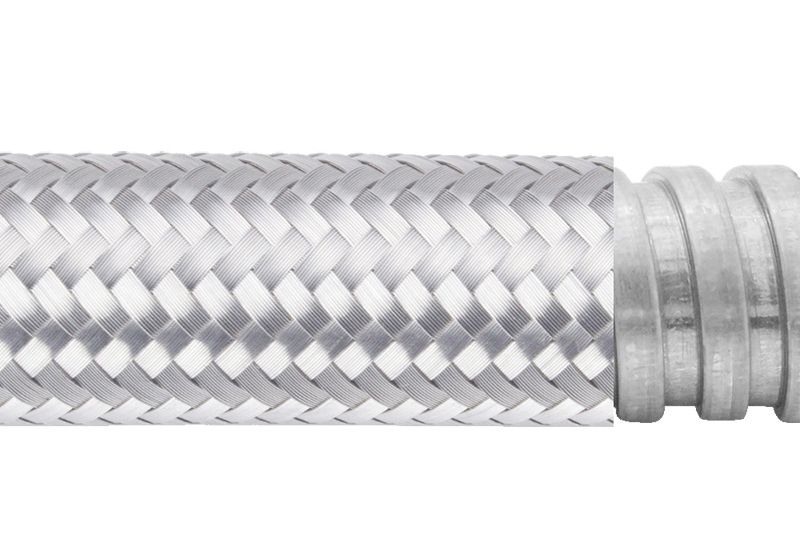

As a Flexible Metal Conduit EMI Proof Manufacturers, share it with you. Some

friends don’t know why they like metal conduit. What is good about him? I don't

even know what he does, but I say one thing, friends will definitely know, that

is, gas stove, a thing that we all use in our lives, do friends know? The

connecting device between the pipe and the cooker is a hose, but after a long

period of use, the hose will often fall off due to the corrosion or looseness of

the bayonet, and the hose will often fall off with the extension of the use

time. The phenomenon of aging and cracking is also very common. Then the

security risks in this one are very big. The emergence of stainless steel metal

hoses perfectly solves these problems, making the use of gas stoves safer and

more reliable, and people can use them in their daily lives.

Flexible Metal Conduit EMI Proof

Requirements for metal conduit installation

1. During the installation process of the metal conduit, the length of the metal

conduit can be adjusted appropriately with the help of a tie rod tool according to

actual needs, and the adjustment amount during the adjustment process shall not

exceed the specified value.

2. During the installation, if the electric welding operation process stage

is carried out, we must take certain measures to effectively protect the metal

hose to avoid the welding slag splashing the corrugated pipe to the greatest

extent.

3. During the installation process, the end of the soft joint of the metal

hose should be reliably and effectively fixed away from the vibration source, so

that the soft joint can effectively absorb vibration.

Points to note in metal hose installation

1. The installation of the metal hose sealing system should be strictly

carried out in accordance with the safety operation regulations, so as to avoid

the stainless steel metal conduit from being pulled off or broken due to improper

operation.

2. When welding the metal conduit, always pay attention to the splashed

material, so as to avoid scalding the stainless steel metal hose and damage the

equipment, resulting in the leakage of the stainless steel metal hose.

3. After the equipment and piping system to be used are subjected to a

hydraulic test, the deposited chloride ion-containing sand should be cleaned up

in time and the impact of the rust block should be prevented to avoid

unnecessary corrosion and mechanical damage.

Our company also has Flexible Metal Conduit EMI Proof on sale, welcome to

contact us.