Apr. 19, 2023

Explosion-proof flexible couplings play a key role in preventing catastrophic accidents by providing a safe and reliable way to transfer power and motion between rotating shafts in equipment such as pumps, compressors, and turbines. In this article, we will explore what explosion proof flex couplings are, their benefits, and how they work.

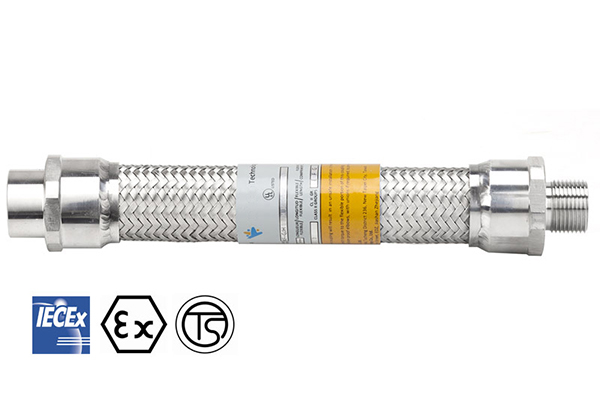

Explosion Proof Flexible Coupling (UL / IECEx)

What are Explosion Proof Flex Couplings?

An explosion proof flex coupling, also known as an explosion proof coupling, is a mechanical device designed to connect two rotating shafts while allowing for some degree of misalignment, axial movement, and torsional vibration. It is constructed from materials that can withstand high temperatures, corrosive chemicals, and potentially explosive atmospheres. Explosion proof flex couplings typically consist of two hubs connected by a flexible element, which can be made from materials such as metal, elastomer, or composite.

Benefits of Explosion Proof Flex Couplings

The main benefit of explosion proof flex couplings is their ability to prevent catastrophic incidents in hazardous environments. By connecting rotating shafts with a flexible and resilient element, explosion proof flex couplings can absorb shock, reduce vibration, and compensate for misalignment, preventing excessive stress on equipment and reducing the risk of component failure. In addition, explosion proof flex couplings can help to prolong the life of equipment and reduce maintenance costs by minimizing wear and tear on components.

How do Explosion Proof Flex Couplings Work?

Explosion proof flex couplings work by transferring power and motion from one rotating shaft to another while allowing for some degree of misalignment, axial movement, and torsional vibration. When two rotating shafts are connected by an explosion proof flex coupling, any misalignment or vibration in one shaft is transmitted to the flexible element, which can bend, twist, or compress to compensate for the movement. This prevents excessive stress on the equipment and reduces the risk of failure or damage.

In addition to providing flexibility and resilience, explosion proof flex couplings must also be constructed from materials that can withstand high temperatures, corrosive chemicals, and potentially explosive atmospheres. Materials such as stainless steel, titanium, and non-sparking alloys are commonly used for explosion proof flex couplings, and the flexible element may be made from materials such as elastomers, composites, or metal bellows.

Applications of Explosion Proof Flex Couplings

Explosion proof flex couplings are used in a wide range of applications across various industries, including chemical processing, oil and gas, mining, and power generation. They are typically used in equipment such as pumps, compressors, turbines, and gearboxes, where they provide a safe and reliable way to transfer power and motion between rotating shafts. Some common applications of explosion proof flex couplings include:

Connecting the drive shaft of a motor to a pump or compressor in a chemical processing plant.

Connecting the drive shaft of a turbine to a generator in a power plant.

Connecting the drive shaft of a conveyor motor to a gearbox in a mining operation.

Connecting the drive shaft of a mixer motor to an agitator in a food processing facility.

Conclusion

Explosion proof flex couplings are a critical component in maintaining safety and reliability in hazardous environments. By providing a safe and reliable way to transfer power and motion between rotating shafts, explosion proof flex couplings can help to prevent catastrophic incidents and reduce maintenance costs. When selecting an explosion proof flex coupling, it is important to consider the specific requirements of the application, including temperature, chemical exposure, and potential for explosion, and to choose a coupling that is designed and constructed to meet these requirements.

If you want to know more information about explosion proof flex couplings , please contact us. We will provide professional answers.