Oct. 30, 2020

As a Flexible Conduit Factory, share with you. In the field of pipe fittings,

it is easy to blur the concepts between metal mesh pipes and metal conduits,

especially when laymen choose such products, it is easy to confuse these two

products. What is the difference between them before?

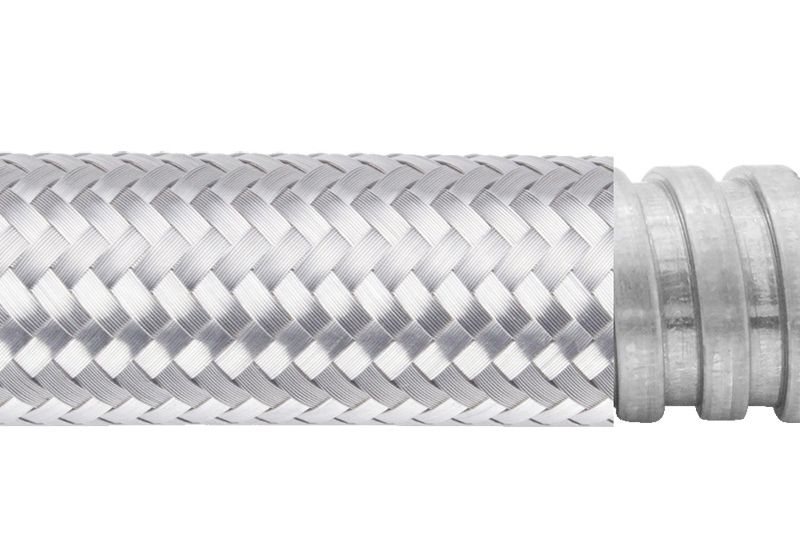

Flexible Metal Conduit EMI Proof

Metal conduit includes threaded metal conduit and corrugated metal conduit,

which are mainly used to protect transmission signal lines, wires and cables,

fiber optic cables, etc. In civilian use, it is mainly used in bathing conduit,

kitchen sink conduit, and industrially used in factory production workshop to

protect cables and wires from external damage. Metal conduit generally has the

characteristics of waterproof, insulation, fire resistance, and tensile

resistance, and has good bending and tensile properties.

The metal mesh tube generally refers to the metal braided tube. It is

composed of multiple layers of inner tubes. Each layer has a different

structure. Generally, the inner layer is a rubber tube, and the middle is an

insulating layer. The appearance is a mesh tube woven of stainless steel wire.

It is used for faucets, toilet pipes, and flowers. Pipe fittings for

sprinkling.

Compared with metal conduits, metal mesh pipes have stronger toughness,

strength, and tensile properties, and are used in more households; metal

conduits are used as infrastructure paving projects and are used more by

enterprises; metal conduits have better sealing properties, but are easy to

break. Metal mesh pipes Low tightness and easy to leak water.

Therefore, it is possible to choose a metal conduit with better sealing

performance or a metal mesh pipe with better toughness according to the actual

situation.

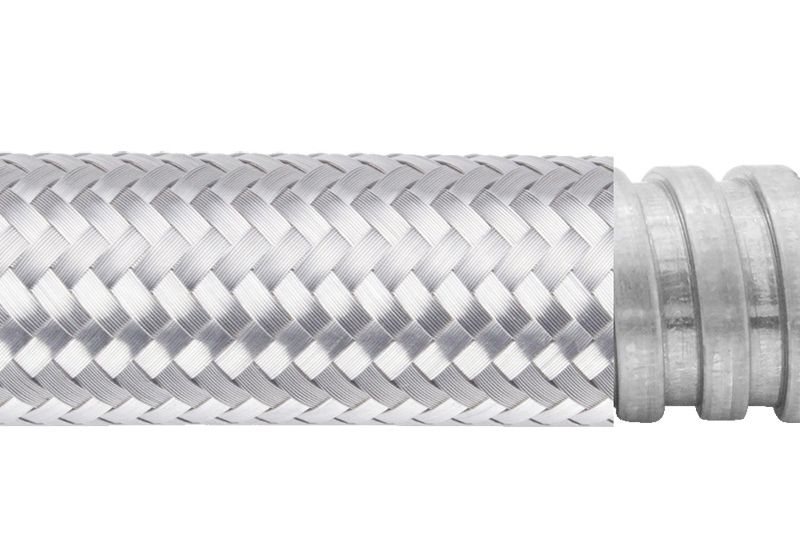

Metal conduit

In complex piping systems, there are often various difficulties in

installation due to the limitations of the space and location conditions: the

formed pipe cannot be installed; bending, straight, and improvising the

installed pipe will inevitably produce partial Cold correction. Depending on the

pipe diameter and the specific situation of the site, the amount of cold

correction ranges from a few millimeters to tens of millimeters, and some up to

hundreds of millimeters. Practice has proved that the larger the amount, the

higher the internal stress, and these remaining installation stresses in the

pipeline system are undoubtedly extremely hidden. A section of the bearing

lubricating oil duct in some types of engines has broken accidents many times in

actual operation because of excessive installation stress.

Since the metal conduit can be bent at will and the internal stress generated

by bending under the condition of the rated bending radius is very small, it can

bring great convenience to the installation work and also play a certain role in

ensuring the safe operation of the pipeline system.

Our company also has Flexible Metal Conduit EMI Proof on sale, welcome to

contact us.