Mar. 02, 2020

As a Flexible Metal Conduit Wholesaler, share with you.

The metal sleeve of the Flexible Metal Conduit is an important aspect of the hose, which

can effectively protect the metal hose and extend its service life. Once the

mesh sleeve of the metal hose is damaged, it will directly affect the hose for a

long time. How to survive the destruction of the metal hose?

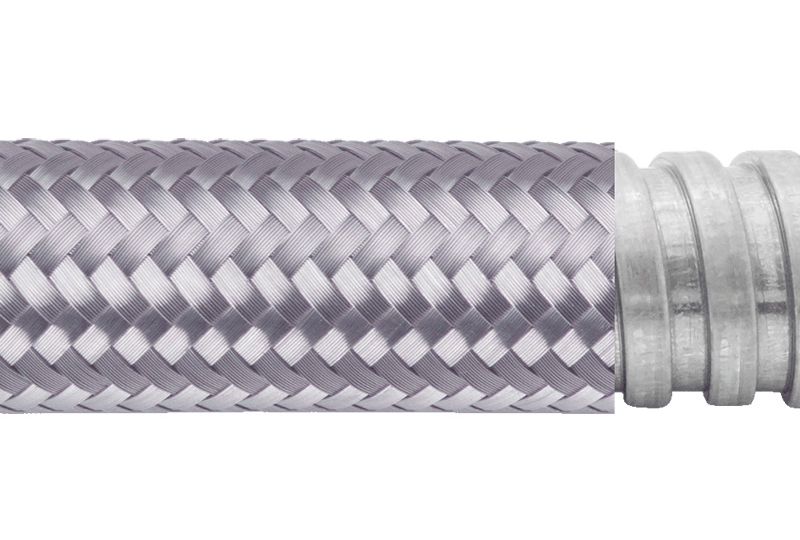

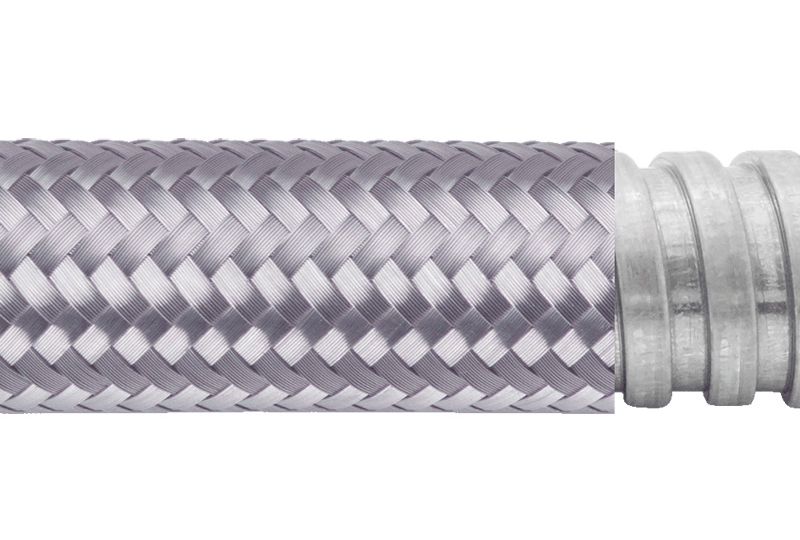

Flexible Metal Conduit EMI Proof-EU

1, Overload causes the net sleeve to break

Overload causes the mesh sleeve to break. When the side pressure of the

medium in the metal hose rises, the stress on the steel mesh sleeve that is

intended to bear pressure will increase greatly. Brokenness will occur.

2. Improper installation causes the net sleeve to break

The setting is not in the industry, and additional stress is applied to the

metal hose, such as rough stretching, light installation, bending, pulling back,

blowing, and rushing will all increase the stress on the metal hose. When the

superimposed stress is excessive on the metal hose When the pole strength of the

steel wire mesh sleeve is broken, the mesh sleeve of the trinity welding part of

the hose or the mesh sleeve of the other parts will be broken.

3. The false welding promotes the pull-out of the mesh sleeve

In view of the cause of the welding quality, the metal hose is transformed

into a heat-melted submerged zone of the mesh sleeve and the flange welding in

the welding long river, so that the bellows, the ring and the steel mesh sleeve

cause part of the steel wire to be damaged during the welding process Soldering,

overheating or not soldering. After the hose is installed on the altar pipe, in

view of the uneven force of the steel wire, under the intention of the medium

down pressure, the steel wire at the virtual welding place is pulled off first,

and then the complete steel wire mesh sleeve is pulled off, which is

dangerous.

4. Etching induces cracking of mesh sleeve

When the corrosive medium is left in the environment, the metal hose mesh oil

will rust, but with the corrosion intensified, most of the outer diameter of the

steel wire will be severely corroded. When the upper pressure of the wire mesh

is increased, the wire mesh sleeve will burst suddenly and violently.

In our real life, we often watch colorful metal hoses. People who do not

understand the industrial production are actually wrong about such and such

products. So what generality does the metal hose have?

First of all, metal hoses are very resistant to corrosion. In addition, the

metal hose also has a very strong security force. For the cable, even if a very

strong current passes through it, it will not be burnt. After it is covered with

a layer of insulator, the safety is relatively high. Because the metal hose

itself has many different properties, it is also widely used.

Our company also has Flexible Metal Conduit EMI Proof-EU on sale, welcome to

consult.