Dec. 28, 2020

As a Flexible Electrical Conduits Supplier, share with you.

Fatigue crack propagation area of flexible metal conduit:

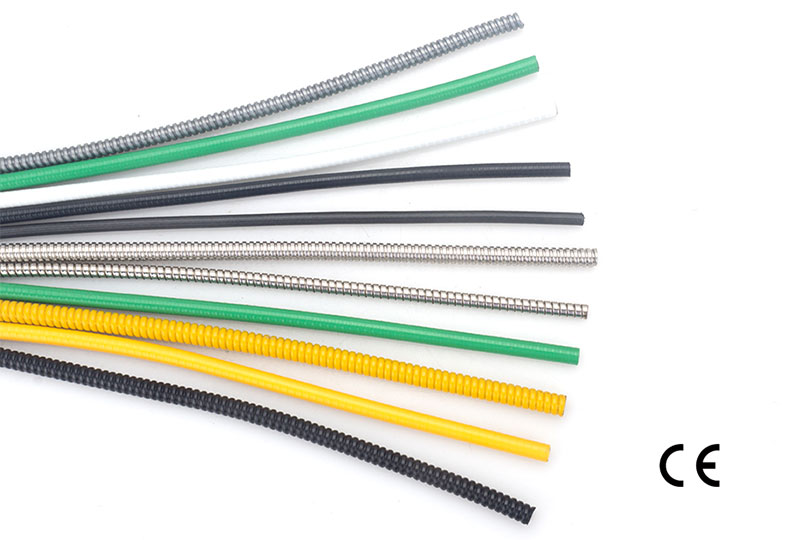

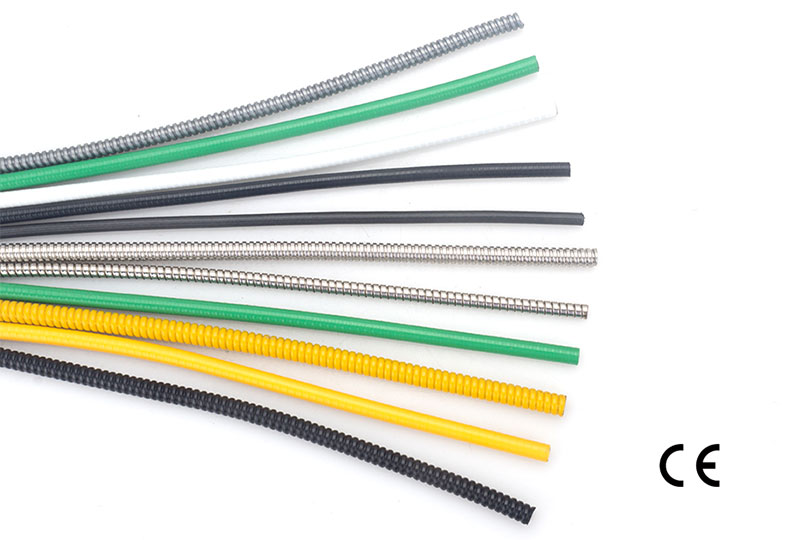

Flexible Electrical Conduits

In general, the micro morphology of the fatigue crack propagation zone has

the characteristics of cleavage or quasi-cleavage fracture. However, when the

material grain boundary is significantly weakened, the fatigue fracture can also

be characterized as intergranular fracture. The morphological features of the

fatigue crack growth zone also include macro fatigue fringes (conchoidal

patterns) and radial fringes. Micro fatigue streaks are traces left by the crack

propagation process under the action of each stress cycle. The micro fatigue

streaks are not continuous due to the microscopic defects of the material

(inclusions, second phases, grain boundaries, etc.) or the difference in crystal

phase , But distributed on small faces of different heights and shapes. The

micro fatigue streaks are slightly curved arcs, usually, the arc center points

to the beginning of the crack. When the material strength is very high, because

it is very brittle, the micro fatigue cracks are not obvious enough on the

cleavage surface of the fatigue fracture. At this time, the fatigue properties

of the component fracture can be determined according to the macro fatigue

streak or the fatigue streak termination line. The radial pattern is another

microscopic feature of the fatigue crack propagation zone. It is the fringe

formed by tearing due to the height difference between different propagation

paths during the fatigue crack propagation process.

According to the above analysis:

The main failure mode of weld cracks in flexible metal conduits is fatigue

cracking, which exhibits the characteristics of rational fracture. However, it

is a general situation that the fatigue lines of austenitic materials with

better toughness mentioned in the textbooks have obvious distribution

characteristics. When the grain boundaries of austenitic materials are weakened,

grain boundary cracks may also appear. Is the fatigue pattern of stainless steel

material itself not particularly obvious? Not necessarily, the state of force,

the direction of force, temperature, environment, etc. will all affect the

morphology of fatigue cracks, but as long as there are macroscopic features of

fatigue shell patterns, it must be fatigue cracking (except for corrosion

patterns). Only the microscopic stripes of fatigue fracture of high-strength

materials are not obvious.

Our company also has Flexible Electrical Conduits on sale, welcome to contact

us.