Jan. 06, 2022

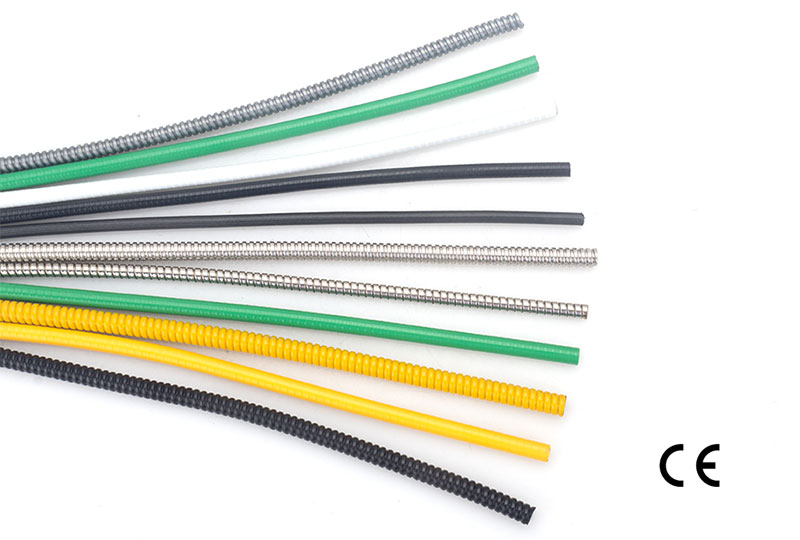

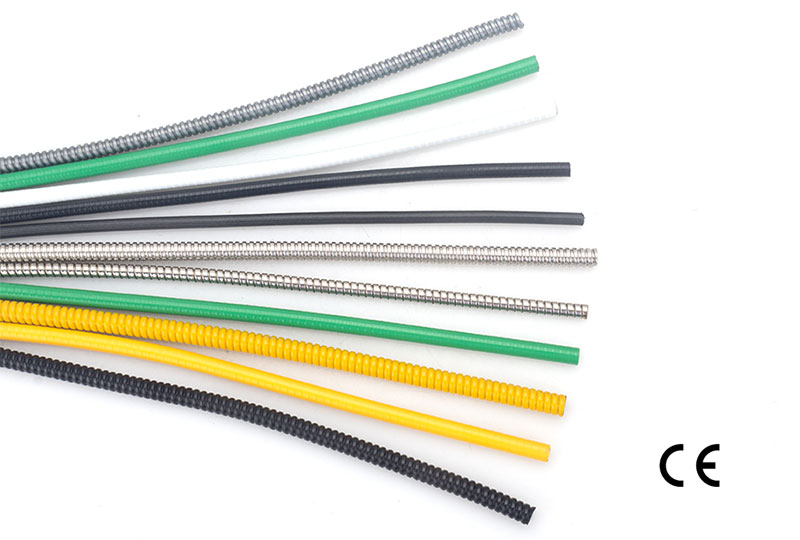

Electrical Flexible Conduit is far easier to use than stiff plastic or metal conduit. This is because there's not any bending involved. But, it won't offer as much security as the stiff kinds of electric conduit. Many DIYers enjoy the creation of flexible electrical conduits since they can use it to install wires . There are a few varieties of conduit that are designed especially for industrial uses, and many others that are ideal for various DIY jobs.

1. Flexible Metal Conduit can also be called FMC and this is a kind of flexible conduit utilized in commercial buildings, especially underground car parks. FMC is produced by coiling metal up and interlocking every one the rings together. This creates a flexible hollow tube that may be employed to pull cables.

This is acceptable for use in arid regions in which it is not feasible to match any kind of rigid conduit. It has sufficient power to guard the cables while still being flexible. This is not, however, waterproof which might be an issue in some specific conditions.

This is acceptable for use in arid regions in which it is not feasible to match any kind of rigid conduit. It has sufficient power to guard the cables while still being flexible. This is not, however, waterproof which might be an issue in some specific conditions.

Rigid conduits like Thin Walled Conduit are basically solid pipes. Special tools are necessary for flexing these conduits. FMC has an edge over Thin Walled conduit since it doesn't require bending. But, it's somewhat more complex to work together and takes a special tool is required to cut it. This instrument was made to cut through the armoring without damaging any Cable Conduits indoors.

2. Liquid Tight Flexible Metal Conduit can be popularly called LFMC and this really is a flexible kind of conduit that covers wires and stays flexible while still being watertight. This sort of conduit was created by Kopex worldwide before patent died and it could now be caused by numerous brands.