Dec. 13, 2023

What Is a Flexible Electrical Conduit?

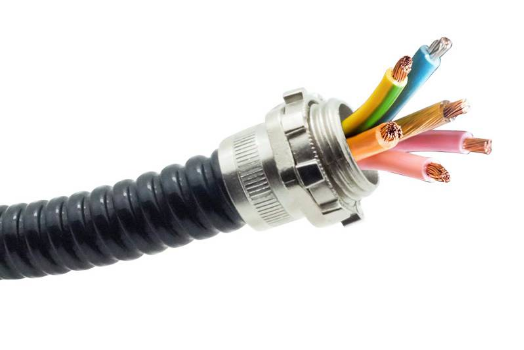

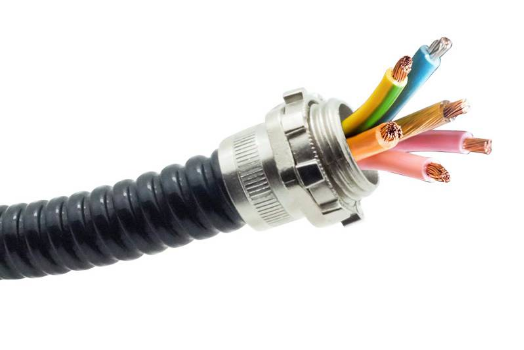

Electrical conduit is a raceway with a circular cross-section that routes and protects electrical wiring in residential, industrial and commercial applications. A flexible electrical conduit is a durable tube that protects electrical wiring in enclosed areas with hard turns, such as in water heaters or lighting fixtures. Conduits, made from materials such as metal, fiber, or plastic, are utilized in the manufacturing process. Electricians install these conduits at specific sites, integrating electrical conduit fittings and liquid-tight jackets to safeguard wiring against stress, corrosion, heat, moisture, and strain.

The primary function of conduit lies in its ability to consistently shield electrical wiring systems from wear and exposure, thereby ensuring safety for individuals, preventing equipment damage, and averting electric shocks. Both local building codes and the National Electrical Code (NEC) dictate the precise locations and methods for conduit installation to guarantee safe electrical operations.

Zhejiang Flexible Technology Co., Ltd. has been producing robust, liquid-tight, and flexible electrical conduit systems since 2007. Our unique methods and specialized tools empower customers to securely link and shield electrical wiring systems in aerial, marine, and terrestrial environments. Rigorous testing of our conduit ensures suitability across diverse industrial, residential, and commercial settings.

Since our inception in 2007, we've manufactured conduit types certified for safe usage according to Underwriters Laboratories (UL) standards. This trademarked conduit is presently utilized globally to safeguard and link optical fibers, cables, and electrical wiring.

Reasons to Install Flexible Conduit Systems

Flexible conduit systems offer robust protection for wiring in challenging environments. Here are several reasons to consider their installation:

1. Use as pull outlets for conductors already in place.

2. Connect different segments of rigid conduit.

3. Link junction boxes to electrical equipment securely.

4. Offer clear transitions and routes for crucial circuits.

5. Connect to wired devices and lighting fixtures efficiently.

6. Enable access to conductors for maintenance and upgrades.

7. Facilitate the creation of 90° bends in conduit pathways.

Types of Flexible Electrical Conduit Offered by Zhejiang Flexible Technology Co., Ltd.

Flexible electrical conduit comes in various types categorized by materials used, wall thickness, tubing size, and mechanical stiffness. The choice of conduit depends on factors such as corrosion resistance and cost.

Zhejiang Flexible Technology Co., Ltd. provides several main types of flexible electrical conduit:

1. Flexible Metal Conduit (FMC):

Standard FMC is ideal for dry, indoor locations, commonly used for shorter runs. This flexible stripwound metal hose is suitable for installations requiring tight bends in confined spaces where rigid conduit won't fit.

2. Liquid-Tight Flexible Metal Conduit (LFMC):

LFMC features a polymer coating and requires sealed threaded fittings for a liquid-tight seal. Available in sizes ranging from 3/8″ to 4”, this conduit is often installed outdoors, in wet conditions, or buried underground. Various metal cores are available for corrosion resistance or electromagnetic shielding, along with polymer jackets meeting specific requirements such as Food Grade, confined space, Halogen Free, or high temperatures.

3. Liquid-Tight Flexible Non-Metallic Conduit (LFNC):

Non-metallic conduit comprises a continuous coil of PVC encased inside flexible PVC material, resistant to oil, heat, and chemical breakdowns. This non-conductive hose utilizes non-metallic or liquid-tight metal connectors for rapid installation. Flame-retardant, durable, and UV-resistant, LFNC is crafted using PVC, boasting a smooth interior and exterior surface while resisting oils and UV rays.

Advantages & Benefits of Flexible Electrical Conduit

Flexible electrical conduit is the preferred choice for contractors in both residential and commercial applications. Some of the advantages of flexible conduit include:

1. Protects conductors from moisture, corrosion, impact, and chemicals

2. Long service life

3. Easy installation

4. Prevents accidental damage to wiring insulation

5. Available in different sizes and types to accommodate any system design or conductor

6. Easily modified

7. Protects against explosions and fire in National Electrical Code Hazardous Locations

8. Resistance to heat and cold for installation in low or high ambient temperature ranges

9. Extremely flexible with tight bend radii

10. Crush-resistant

Flexible electrical conduit can be buried in concrete or underground. A metallic conduit creates an effective shield for protecting sensitive circuits against electromagnetic interference (EMI). Conduit jackets are resistant to radiation, oil, heat and cold. Extruded polymer jackets are available in a vareity of colors.

Conclusion

Flexible electrical conduits are essential components within systems that function in demanding environments. Understanding the available types of electrical conduits, their advantages, and the rationales for installation empowers you to make informed decisions tailored to your application.

Feel free to reach out to us to discuss your specific requirements or to request information regarding our wide range of products.