Oct. 22, 2023

Flexible metal conduit (FMC) is an important component in electrical systems used for the protection and routing of electrical wiring and cables. It comes in various materials, with aluminum and galvanized steel being two common choices. Understanding the differences between these materials is crucial when selecting the appropriate flexible metal conduit for your specific electrical application. In this guide, we'll explore the distinctions between aluminum and galvanized steel FMC.

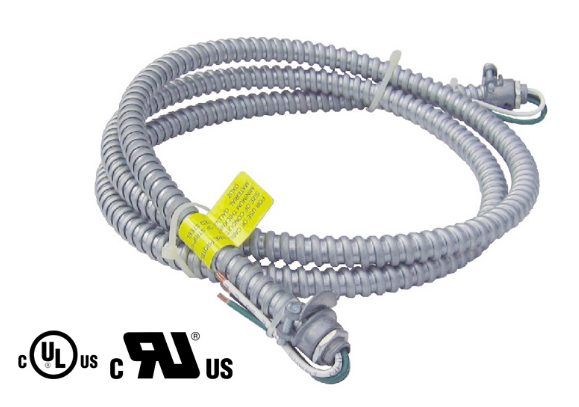

Aluminum Flexible Metal Conduit

Aluminum flexible metal conduit is made from aluminum metal and is a versatile choice for a range of applications. Here are the key characteristics and benefits of aluminum FMC:

Characteristics of Aluminum FMC:

1. Lightweight: Aluminum is a lightweight material, making aluminum FMC easier to handle and install compared to galvanized steel. This can be particularly advantageous in applications where ease of installation is a priority.

2. Corrosion Resistance: Aluminum has natural corrosion resistance properties, making it suitable for outdoor applications or locations with a high degree of moisture or humidity.

3. Non-Magnetic: Aluminum is a non-magnetic material. This can be beneficial in certain applications where magnetic interference or attraction is a concern.

4. Flexibility: Aluminum FMC is known for its flexibility, which allows it to bend and route easily. It is often used in applications where the conduit must navigate around corners or obstacles.

Applications of Aluminum FMC:

- Indoor and Outdoor Wiring: Aluminum FMC can be used for both indoor and outdoor electrical installations, providing protection for wiring and cables against physical damage and moisture.

- Commercial and Residential Construction: It is commonly used in commercial and residential construction for various wiring applications.

- Industrial Settings: Suitable for certain industrial environments where corrosion resistance is required, but mechanical protection is not the primary concern.

- Solar Power Installations: Aluminum FMC can be used in solar panel installations, where exposure to the elements is a consideration.

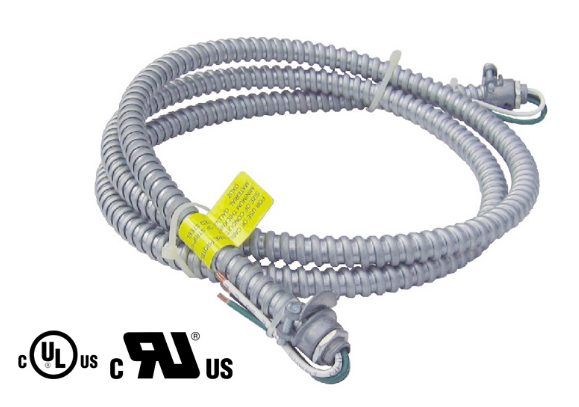

Galvanized Steel Flexible Metal Conduit

Galvanized flexible metal conduit is made from steel that has been coated with a layer of zinc for added protection. Here are the key characteristics and benefits of galvanized steel FMC:

Characteristics of Galvanized Steel FMC:

1. Durability: Galvanized steel is known for its durability and mechanical strength. It provides robust protection for electrical wiring and cables, making it ideal for applications where mechanical protection is crucial.

2. Fire Resistance: Some types of galvanized steel FMC offer fire resistance properties, making them suitable for applications where fire safety is a concern.

3. Temperature Resistance: Galvanized steel is capable of withstanding high temperatures, making it suitable for applications in areas where heat resistance is essential.

4. EMI/RFI Shielding: Galvanized steel provides electromagnetic interference (EMI) and radiofrequency interference (RFI) shielding, which is essential for protecting sensitive electronic equipment from external interference.

Applications of Galvanized Steel FMC:

- Industrial Settings: Galvanized steel FMC is widely used in industrial environments, factories, and manufacturing facilities where the conduit must withstand harsh conditions and provide mechanical protection.

- Commercial Buildings: Suitable for electrical installations in commercial buildings, especially those that require EMI/RFI protection or fire resistance.

- Outdoor Wiring: In situations where added mechanical protection is required, such as outdoor wiring runs exposed to potential physical damage.

- Underground Installations: Galvanized steel FMC can be used for burying electrical wiring underground in areas with minimal exposure to moisture.

Key Differences Between Aluminum and Galvanized Steel FMC

1. Material Composition:

- Aluminum FMC: Made from aluminum metal, which is lightweight and naturally corrosion-resistant.

- Galvanized Steel FMC: Made from steel coated with a layer of zinc for added protection, offering enhanced durability and mechanical strength.

2. Weight:

- Aluminum FMC: Lightweight and easy to handle, which simplifies installation.

- Galvanized Steel FMC: Heavier and may require more effort during installation.

3. Corrosion Resistance:

- Aluminum FMC: Naturally corrosion-resistant, making it suitable for outdoor and high-moisture applications.

- Galvanized Steel FMC: Provides corrosion resistance through the zinc coating. However, it is not as naturally corrosion-resistant as aluminum.

4. Fire Resistance:

- Aluminum FMC: Typically not chosen for its fire resistance properties.

- Galvanized Steel FMC: Some types offer fire resistance, making them suitable for applications where fire safety is a concern.

5. EMI/RFI Shielding:

- Aluminum FMC: Does not provide significant EMI/RFI shielding.

- Galvanized Steel FMC: Offers natural EMI/RFI shielding, making it suitable for applications with sensitive electronic equipment.

6. Temperature Resistance:

- Aluminum FMC: May not withstand high temperatures as effectively as galvanized steel.

- Galvanized Steel FMC: Capable of withstanding high temperatures, making it suitable for applications in areas with heat.

Conclusion

The choice between aluminum flexible metal conduit and galvanized steel flexible metal conduit depends on the specific requirements and conditions of your electrical project. Aluminum FMC is lightweight, corrosion-resistant, and flexible, making it suitable for a wide range of applications. On the other hand, galvanized steel FMC provides robust mechanical protection, fire resistance, and EMI/RFI shielding, making it ideal for industrial, commercial, and applications where durability is critical. Carefully assessing your project's needs and the environment it will operate in will guide you in making the right choice between these two types of conduits.