Sep. 14, 2023

Yes, a metallic flexible conduit can indeed be covered by a waterproof plastic coating, and this combination offers a highly effective solution for protecting electrical wires and cables in environments where moisture and water exposure are a concern. In this detailed exploration, we will delve into the benefits, applications, and considerations of using metallic flexible conduit with a waterproof plastic coating.

Understanding Metallic Flexible Conduit

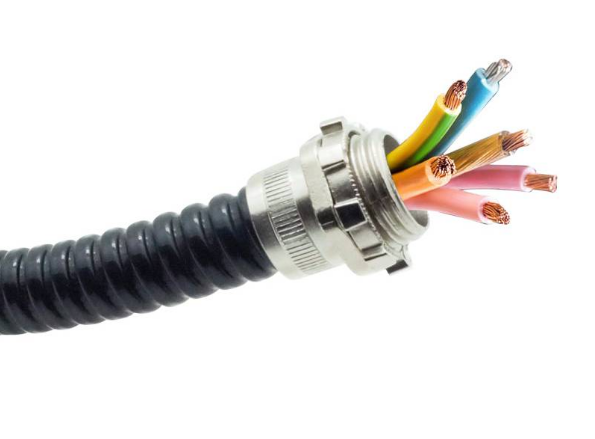

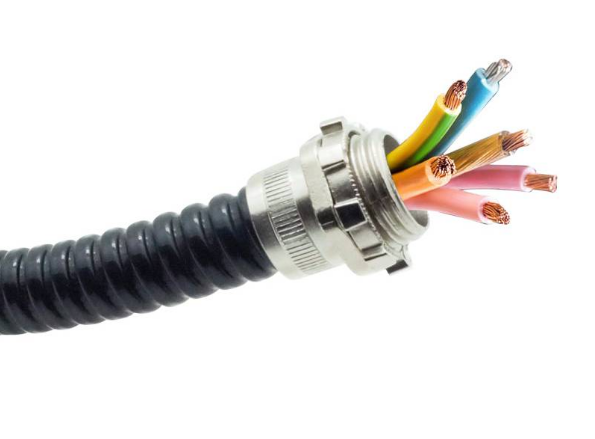

Before delving into the specifics of a waterproof plastic coating, let's first establish a clear understanding of metallic flexible conduit (FMC) itself. FMC is a versatile and durable conduit system used to protect electrical wiring. It is typically made from helically wound metal strips, commonly steel or aluminum, which provide rigidity and strength while allowing for flexibility.

The primary purpose of FMC is to safeguard electrical wires and cables from various environmental factors, including physical damage, corrosion, and moisture. While standard FMC provides a degree of protection against moisture, adding a waterproof plastic coating takes this protection to a whole new level.

Benefits of a Waterproof Plastic Coating

1. Enhanced Moisture Resistance:

The most significant advantage of a waterproof plastic coating is its ability to create a barrier that prevents moisture and water from infiltrating the conduit. This is particularly crucial in wet environments, such as outdoor installations, bathrooms, kitchens, and industrial settings.

2. Corrosion Prevention:

Moisture is a significant contributor to corrosion, especially in metallic conduits. The plastic coating acts as an additional layer of defense, inhibiting the formation of rust and corrosion, which can compromise the integrity of the conduit over time.

3. Chemical Resistance:

In some environments, there may be exposure to chemicals that can be harmful to metallic conduits. The plastic coating can provide resistance to a wide range of chemicals, ensuring the conduit's longevity.

4. Flexibility and Durability:

The plastic coating does not compromise the flexibility of the conduit. It retains the conduit's ability to bend and navigate tight corners while adding an extra layer of protection. This combination of flexibility and durability is especially valuable in complex installations.

Flexible Metal Conduit WaterProof

Applications of Metallic Flexible Conduit with Waterproof Plastic Coating

The versatility of metallic flexible conduit with a waterproof plastic coating makes it suitable for various applications across different industries. Here are some common use cases:

1. Outdoor Installations:

In outdoor electrical installations, exposure to rain, snow, and other weather elements is a constant concern. The waterproof plastic coating ensures that the conduit remains dry and corrosion-free.

2. Bathrooms and Kitchens:

These areas in residential and commercial buildings are prone to high humidity and occasional water splashes. Using conduit with a plastic coating protects the electrical system from moisture-related issues.

3. Industrial Facilities:

Industrial environments often involve exposure to both moisture and harsh chemicals. The combination of a metallic conduit's strength and the plastic coating's chemical resistance makes it an ideal choice in these settings.

4. Marine Applications:

Conduits in marine environments are subjected to constant exposure to saltwater, which can be highly corrosive. A waterproof plastic coating is essential to prevent rust and maintain electrical system integrity on ships and offshore platforms.

Considerations When Using Conduit with a Waterproof Plastic Coating

While the benefits of using metallic flexible conduit with a waterproof plastic coating are clear, it's essential to consider a few factors when planning your installation:

1. Proper Installation:

Ensure that the conduit with the plastic coating is correctly installed, with sealed connections and fittings. Proper installation is critical to maintaining the conduit's waterproof properties.

2. Compliance with Codes:

Always adhere to local electrical codes and regulations when using conduit in electrical installations. Compliance ensures safety and prevents potential issues during inspections.

3. Temperature Variations:

Consider the temperature range of your installation environment. Some plastic coatings may have temperature limitations, so choose a coating that can withstand the expected temperature fluctuations.

Conclusion

A metallic flexible conduit covered by a waterproof plastic coating is a reliable and efficient solution for protecting electrical wiring in environments prone to moisture and water exposure. Its enhanced moisture resistance, corrosion prevention, and flexibility make it an excellent choice for a wide range of applications, from outdoor installations to industrial settings. However, proper installation and adherence to local codes are crucial to maximize the benefits of this conduit system.

If you want to read more information about metallic flexible conduit, please click on the image below to get a free quote: