Jul. 15, 2022

Flexible steel conduits are manufactured to BS EN 61386-23 in galvanised or stainless steel. They’re commonly available in sizes from 20 to 50mm and with a range of coverings, such as a PVC over-sheath, a low fire hazard coating and a braided steel covering. The braided steel covering provides EMC screening. In addition, a range of metal glands and other accessories are available.

Galvanized Steel Flexible Metal Conduit (Reduced Wall)

Can Flexible Metal Conduit Be Used for Earth Continuity?

Regulation 543.2.3 prohibits the use of flexible metal conduit as a protective conductor. Therefore, it will be necessary to run a separate circuit protective conductor (cpc) with the flexible conduit and, for aesthetic purposes, it would be best to run the cpc inside the conduit rather than fix it by means of tape or ties to the outside of the conduit.

Why is electrical continuity required for metallic conduit?

If your metal conduit is the sole earth conductor for the end circuit then a very good connection of conduit joints is essential. That doesn’t happen by chance. It can occur if every joint is clean, dry, tight and not continuously flexed. I see systems where the earth continuity is still good after multiple decades and joints where they are undone show shinny unrusted steel.

Even if you are installing a separate earth wire or a composite cable containing an earth within your conduit, the conduit sections still need an earth to avoid the possibility of a fault livening the conduit and not having a fault path back to the supply.

Another consideration is if the metal conduit is there to act as a shield for the conductors. Either to keep the signal on the conductors unaffected by other conductors or sources of magnetic fields. Or to keep the noise/harmonics associated with a Variable Speed Drive or Soft Start contained to the power cables connected to it. In either case a good connection from end to end of the conduit would be essential again.

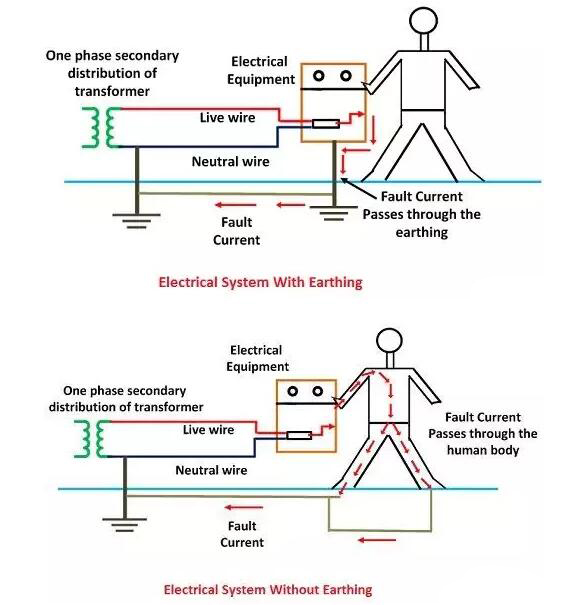

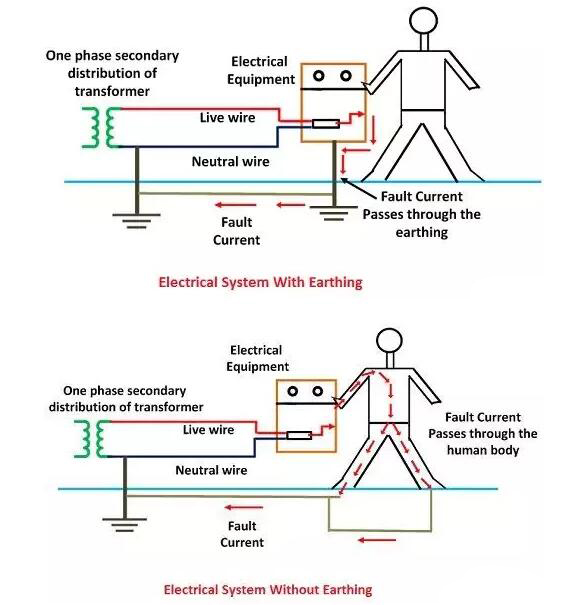

Why is earthing necessary in electrical systems?

There are three wires which run through the domestic electrical circuits.

1. Live wire

2. Return or Neutral wire

3. Ground or Earth wire.

In a normal situation when an appliance is switched on the circuit completes it's path from live wire to return wire.

But in case if a splice of live wire comes in contact with the metal part of the appliance, then the user has chance of getting shock because he completes the circuit with groumd as the return condutor.

In order to ensure safety of the users, a simple concept of current is followed I.e. current flows through the lowest resistance path. A Earth wire of the domestic household is connected to all the power appliances which connected to the earthing pit and Earth point at the METER.

With the Earth wire now the circuit from appliance metallic Parth to Earth wire is the lowest return path so the users are saved from electrical shock.

The resistance of the Earth wire circuit is in the order of tens of ohms where ad the resistance of Human body is between 500 k ohms to Mega ohms.

How is the alignment of electrical conduits embedded in slabs ensured?

Safety Caution:

Do not attempt to work on your electrical wiring, switches, or outlets unless you are properly trained and equipped to do so. Electrical components in a building can easily cause an electrical shock, burn, or even death.

Before doing any work on the wiring & switch, the power source must be turned off by set�ting a circuit breaker to OFF or removing a fuse.

The only mechanism to check the alignment of electrical conduits in slabs is through the visual inspection.

The electrical conduits, generally PVC pipes are laid immediately after the bottom rebar mat of slab is done. That means, the conduits should be laid in between the bottom and top mat of slab reinforcement.

The conduits shall be tied with a binding wire of MS or GI as per specification to keep intact with the rebar.

Always the conduit shall be run in a straight path. In case of bend and curvature, the conduit shall be laid in such a manner that it doesn't obstruct while drawing of wires.

Whenever more than two conduits are to be laid adjacent to each other, a gap of 25 mm must be provided for ease of flow of concrete.