Jan. 27, 2022

In this article, we will discuss armored and unarmored fiber optic cables and the various cable constructions offered. I will also discuss the advantages and disadvantages of armored versus unarmored cables in these different constructions.

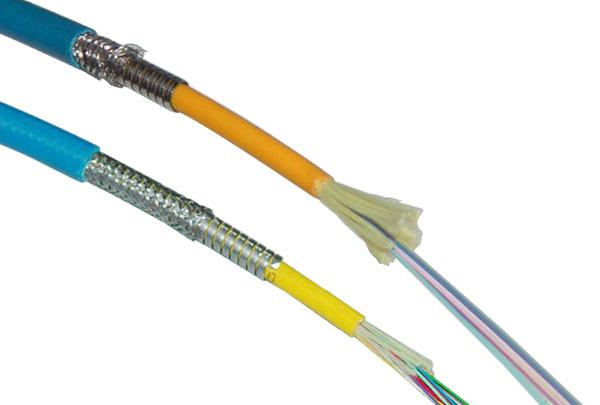

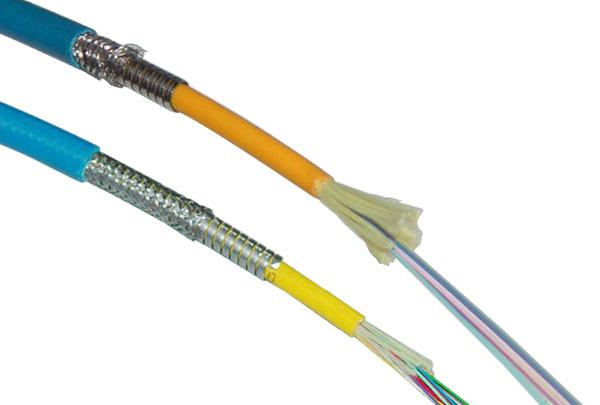

Fiber optic cables are offered in two different types of armor: aluminum interlocking armor for indoor cables and corrugated steel tape for outdoor cables. The armor provides an additional layer of mechanical protection for the cable. The difference between the two types of armor is the material of the armor and the way it is applied to the cable. Aluminum interlocking armor is made of - you guessed it - aluminum - which is spirally wrapped around the fiber optic cable. This type of armor is used for indoor rated cables. The second type of armor is corrugated steel tape. This armor consists of coated corrugated steel that is folded lengthwise around the cable. Corrugated steel tape is found in outdoor rated cables. Fiber optic cables are available in many different cable constructions, each with its own advantages and disadvantages. Armored cables have some benefits when it comes to installation, and there are certain applications where it is more cost effective to use this cable. Some of these cables are more versatile than others, and if you have some on hand, it may help you be prepared for any situation (such as an unexpected network outage). Other times, the decision will depend on the engineer and the type of cable they prefer. There are associated costs that can help you decide on the style you choose. Armored cable costs more than unarmored cable, but the labor to install it may be cheaper, which can make installing armored cable more feasible. Below we will discuss several different cable constructions and the choice you can make between the two, armored and unarmored.

Power Distribution Cables

Distribution cable is a tightly cushioned cable construction; inside the outer sheath is a layer of aramid yarn and multiple fibers with a 900um tightly cushioned sheath. Distribution cables are multi-fiber cables for indoor applications. The color of the single-mode outer jacket is usually yellow, while for multimode, the outer jacket can be orange, light green, magenta or light green, depending on the multimode fiber type. The fiber has a 900-micron sheath on it, which allows you to terminate connectors without stacking on the fiber. Where this cable is laid indoors will help determine if armoring is required. When running fiber optic cables in harsh environments or high traffic areas, it is best to have the additional protection of an armored cable. This may be in a warehouse environment or above a ceiling that is regularly visited. Indoor armored cables use aluminum interlocking armor to help protect the fiber optic cable while increasing the durability of the fiber run. Sometimes you may need to run cable in indoor conduit. Aluminum interlocking armored cable helps eliminate the need for conduit and can replace running conduit. Installing conduit increases installation costs because you must spend time placing the conduit. You then have to pull the cable through the conduit, which means you have effectively doubled the cost of labor to perform the installation. With aluminum interlocking armored cable, you now only have to pull the cable once.

Indoor Outdoor Cables

Another type of cable that offers armored or unarmored construction is indoor-outdoor cable. This type of cable usually has a black UV resistant outer sheath and a moisture resistant material in the cable's Kevlar or Aramid yarn. You can use two different types of indoor-outdoor cables. One is called distribution and it will have a 900um tight buffer like the indoor distribution cable we talked about above. The indoor/outdoor distribution is the same construction as the distribution cable above, except that it has a special black UV protective jacket to protect the fiber inside from sunlight.

Indoor/Outdoor can also be used as a dry loose tube construction. This is where the fibers have only a 250um acrylate coating and they are arranged in separate buffer tubes with 12 color-coded bare fibers in each tube. These are similar to the next category - external plant cables, but they do not contain any water-blocking gel, hence the "dry" name. Similar to distribution cables, these cables can be armored or unarmored. The armor used in the cable is aluminum interlocking armor. This type of cable cannot be buried directly, but the armor provides some additional protection for the fiber in harsh environmental settings. Installers typically use it when they need to run it indoors as well as outdoors for some distance. Without the need for an interconnection box at the building entrance to transition from outdoor to indoor cable.

This type of unarmored cable can be used in a variety of applications because it is so flexible in how it can be deployed. Since you can run this cable inside or outside, some contractors will purchase this type of cable just in case because they can use it for a variety of applications. This gives them the flexibility to handle multiple situations without having to carry multiple different spools of cable.

Outside Plant (OSP) Cable

External Plant Cable is a cable construction that is typically coated with gel or Icky Pic over bare fibers to provide additional protection against water. osp cables operate in underground or aerial applications. These gel-filled cables can only be run in buildings up to 50 feet because of the toxicity of the smoke and fumes produced during combustion. Building codes specify this distance and the cable needs to be inspected after installation. The way this cable is installed will help determine if you need to armor it. Aerial and buried applications can use armored or unarmored outdoor fiber optic cables. Here, we will focus on when the cable is buried.

When you are talking about buried exterior plant cables, you have a few options to complete the installation. The first option relates to unarmored cable and involves the use of conduit or internal conduit. When you lay conduit underground, you don't need armored fiber, but you can use it as needed because it makes the cable more robust and helps to locate the cable later.

Armored external plant cables can be buried directly without the use of conduit. This type of cable construction uses corrugated steel tape as the armor. When you bury the cable, know how deep the frost line is in your area because the cable needs to be buried below that line. The cable is buried below the frost line so it will not be damaged when the ground freezes and "freezes and swells". Armored cable is not only suitable for direct burial, but also for rodent protection. So, if you have trouble with rodents, it would be wise to use armored cable. Keep in mind that armored cables need to be connected and grounded to protect against lightning strikes, especially when used for aerial applications.

What does the connection and grounding of the cable do? Basically, the connection and grounding of an armored fiber optic cable protects the cable and the equipment it connects to from currents such as those from faulty or exposed wires or lightning strikes.

While this article does not cover all applications in detail, it does give you an idea of several different cable constructions and armored versus unarmored applications. Remember, when you are performing a fiber optic cable installation, whether it is your first time or you are a seasoned veteran, you should be sure to do a good job of geographically operating the installation location as well as mapping the path you need to take to perform the installation.