UL 514B: Liquid Tight Flexible Metal Conduit Fitting

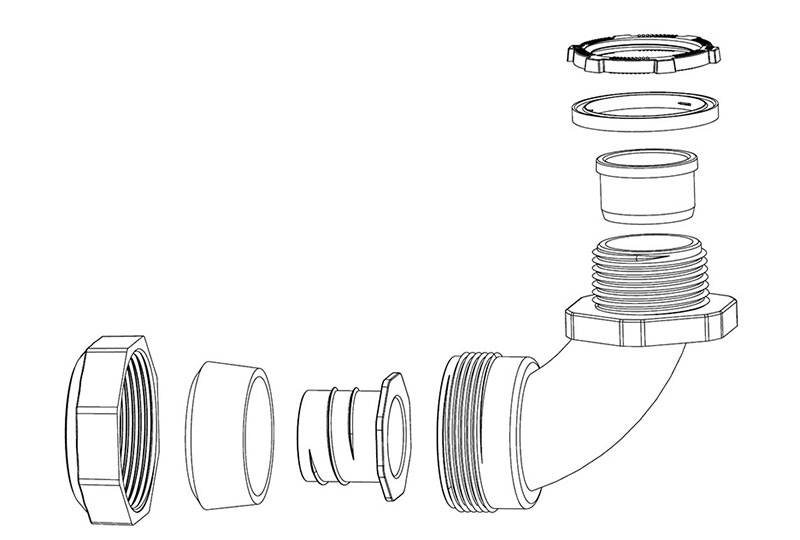

Liquid Tight Metal Conduit Fitting S53 series is certified by UL laboratory according to UL514B and Canadian CSA-C22.2 No.56 standard. S53 series metal fittings are applied on the relay or end point of wiring system to connect metal conduits, junction box or enclosure for wiring extension and protection. The body is made of zinc alloy with RoHS compliance. The fitting is fixed to the junction box or tapped entries by locknut with male NPT thread system and connected with metal flexible conduit by a nut. This series of connector is designed to 90-degree elbow that is particularly applicable for limited space where the wiring system ended to a junction box or enclosure. The compact structure of this fitting offers feature of moisture and water seal and high tensile resistance to protect the wiring system and benefit to apply to indoor or outdoor environments after assembled with the liquid tight metal flexible conduit series PULTG, PCBLTG, PHLTG and PNKLTG.

Material:Zinc Alloy

Temperature Range : -20℃~+90℃

IP Rating : IP 66 (Fit with conduit series: PULTG, PCBLTG, PHLTG & PNKLTG)

Surface Finish : Chromate, other treatments are available by consult.

RoHS Compliance : Yes

Certificate : UL, cULus

| Nominal Conduit Size (mm) | Nominal Conduit Size (inch) | NPT Thread | Part Number | Package / Box (Pcs) | Weight / Box (Kg) |

|---|

| 12 | 3/8 | 1/2" | S531 - 3/8 | 200 | 16.2 |

| 16 | 1/2 | 1/2" | S532 - 1/2 | 200 | 17.2 |

| 21 | 3/4 | 3/4" | S533 - 3/4 | 160 | 18.6 |

| 27 | 1 | 1" | S534 - 1 | 100 | 19 |

| 35 | 1-1/4 | 1-1/4" | S535 - 1 -1/4 | 39 | 12.7 |

| 41 | 1-1/2 | 1-1/2" | S536 - 1 - 1/2 | 30 | 12.7 |

| 53 | 2 | 2" | S537 - 2 | 16 | 9 |

| 63 | 2-1/2 | 2-1/2" | S538 - 2 - 1/2 | 12 | 12.6 |

| 78 | 3 | 3" | S539 - 3 | 8 | 12.2 |

| 103 | 4 | 4" | S5310 - 4 | 4 | 9.4 |